Hickling and Squires

a Nottingham-based printing specialist

Additionally, the setup enhances their existing operations: “The high precision drag knife allows us to intricately cut our coating blankets for our three Heidelberg presses, creating detailed varnish areas,” Gilbert added.

The transition to in-house production was seamless, with the IGS team managing a smooth installation process. “We were ready for production within hours of delivery, and the training for handling a wide range of rigid materials we stock has been excellent,” Gilbert noted.

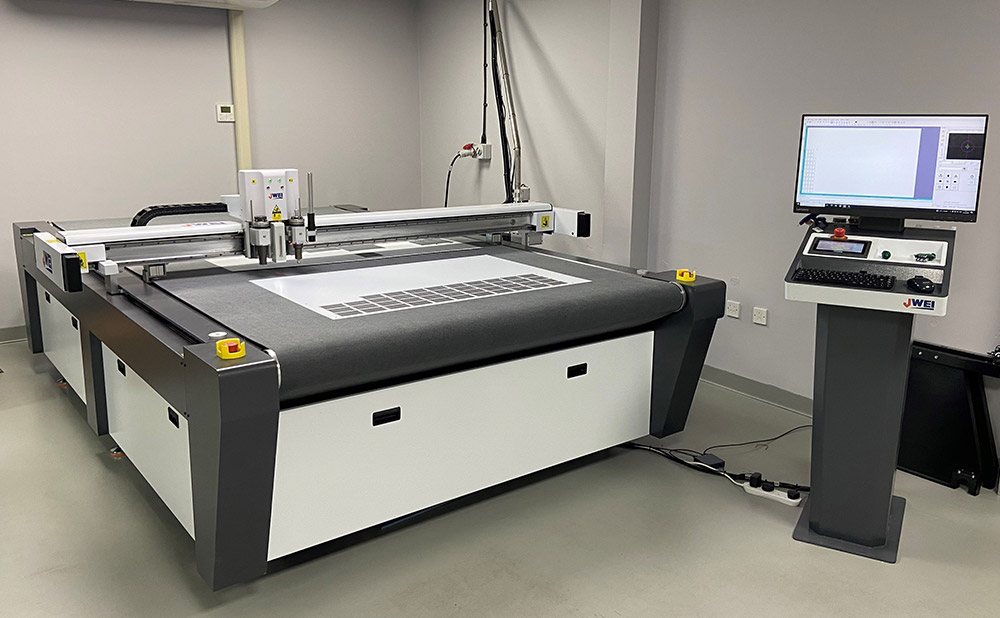

The Titanium 2516, purchased from Monmouthshire-based International Graphics Supplies, is part of a broader series of cutting tables. These range from the fully automatic Titanium 0912, ideal for those entering the short-run packaging market, to larger formats up to 3.0 x 3.2 meters for extensive wide format printing needs. Each machine includes a high-resolution registration camera to ensure precise cuts, along with standard tools such as drag knives, oscillating knives, kiss-cut knives, V-Cut knives, and creasing wheels. Specialty tools available include routers and rotary tools for textiles, providing versatility across various materials, from Dibond and corrugated materials to woods and plastics.

Peter Flynn, Managing Director at IGS, commented on the installation: “I’m very pleased to see Hickling and Squires are already enjoying the many benefits of a Titanium cutter. As Jamie has noted, our price-to-performance ratio is difficult to match, and this powerful combination is helping us build a very impressive portfolio of customers.”

With this new capability, Hickling and Squires are set to enhance their operational efficiency and expand their market reach, offering a wider array of high-quality printed products directly to their clients.