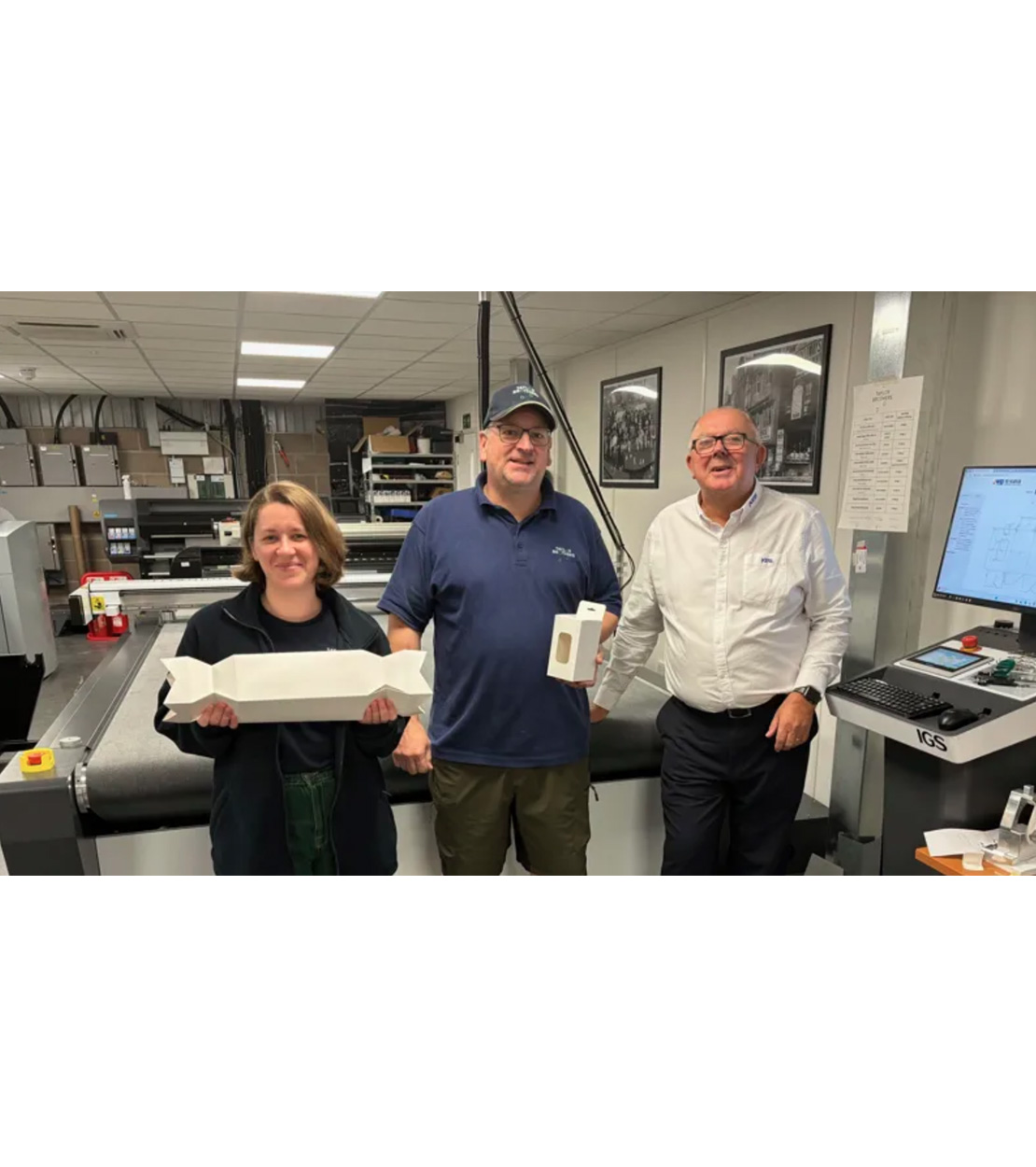

Taylor Brothers,

The Titanium 2516 also promises to free up resources for other business areas, further supporting their growth strategy.

IGS Managing Director Peter Flynn remarked: “Taylor Brothers is renowned for its print precision and quality. After understanding their needs, we knew the Titanium 2516 with router and our PS packing software would be an ideal match.”

The integration of IGS’s PS software has already enabled Taylor Brothers to offer a wide variety of packaging prototypes, benefiting both existing and new customers. According to Shield, the software’s extensive library of box and POS designs allows them to efficiently produce short-run cut/crease and kiss-cut products, complementing their existing Heidelberg Versafire digital presses.

With the Titanium 2516’s large cutting bed (2.5×1.6m) and conveyor belt system, the company can now produce a range of wide-format products, including wall, floor, and window graphics, as well as banners.

An additional benefit of the machine is its high-precision drag knife, which allows Taylor Brothers to cut Heidelberg B2 litho coating blankets for intricate varnish areas.

Taylor Brothers has been a part of Bristol’s printing landscape since 1832. A management buyout in 2018 saw a team of six employees take ownership of the company, and in the same year, they relocated to a modern 1,020sqm facility just two miles from Bristol’s city center.

With this latest investment in cutting-edge technology, Taylor Brothers is well-positioned to continue delivering top-tier print solutions while expanding its service offerings.